Technical Parameters

| MT 1060 Automatic Stamping And Die-Cutting Machine | |

| Model | MT 1060 Automatic Stamping And Die-Cutting Machine |

| Max.paper size | 1080×800mm |

| Min.paper size | 400×360mm (Option servo paper delivery 370×270) |

| Max.die-cutting size | 1070×770mm |

| Die-cutting precision | ±0.09mm |

| Max.working pressure | 380T |

| Max.working Speed | 7200P/H |

| Air requirements | 0.6~0.8mp 0.36m³ |

| Paper thickness | White card/plastic sheet:0.1~1.5mm Grey board:<2.5mm Corrugated paper:<6mm |

| Gripper range | 3~8mm |

| Motor power | 11Kw |

| Heating power | 21.6Kw |

| Servo total power | 13.9Kw |

| Total power | 51.5Kw |

| Working power | 30Kw |

| Weight | 18T |

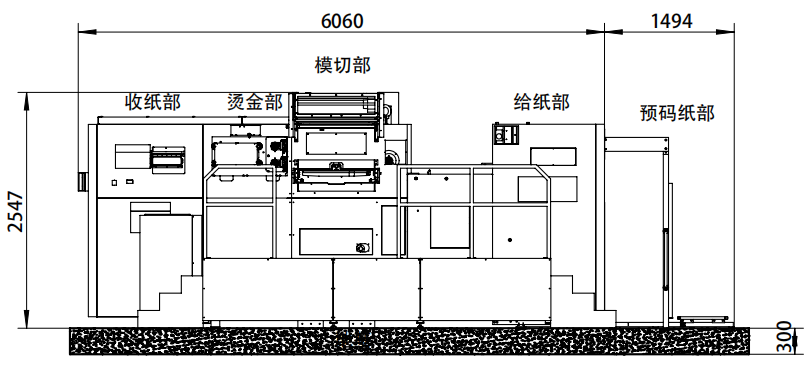

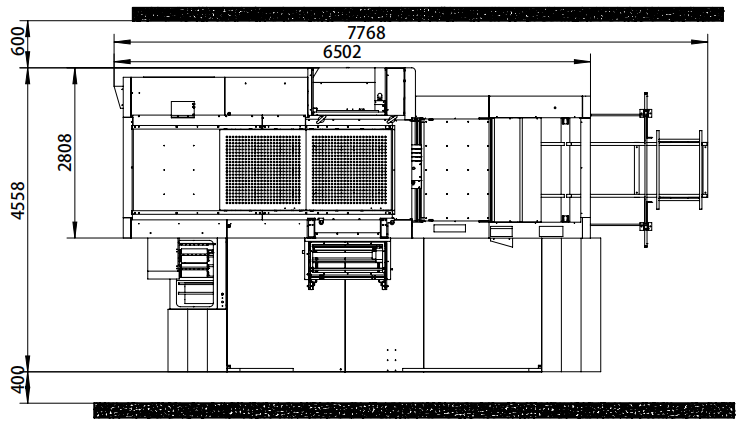

| DimensionsDimensions | 6060×2808×2547mm pedal width 1750 |

Sketch

MT 1060 Automatic Stamping and Die-Cutting Machine

The MT 1060 Automatic Stamping and Die-Cutting Machine is a high-precision post-press finishing solution designed for modern printing and packaging industries. It combines automatic die-cutting, stamping, and creasing in one system, delivering consistent, high-quality results while improving production efficiency.

With servo-driven sheet feeding, intelligent pressure control, and a user-friendly touch-screen interface, the MT 1060 is ideal for paperboard, cardboard, laminated sheets, and specialty substrates. Its applications include luxury packaging, gift boxes, book covers, promotional products, and specialty labels.

This document provides a detailed guide on operation methods, maintenance frequency, upkeep techniques, and performance characteristics to ensure optimal machine performance and longevity.

The MT 1060 is designed with advanced technologies to maximize productivity and precision.

Combining die-cutting, stamping, and creasing in one operation reduces material handling, ensures perfect alignment, and shortens production time.

Servo-controlled feeding ensures micron-level alignment for accurate die-cutting and stamping, even for complex multi-color designs.

Adjustable pressure zones ensure uniform cutting and stamping across sheets of varying thicknesses.

The vacuum-assisted sheet feeder guarantees smooth, accurate placement for consistent production.

Operators can quickly adjust parameters such as sheet size, speed, and pressure. The interface also stores production programs for repeat jobs.

A cast-iron frame minimizes vibration and ensures consistent embossing and cutting depth, even during high-speed production.

Equipped with emergency stop buttons, interlocked doors, and overload protection, the MT 1060 ensures operator safety and reduces machine downtime.

| Parameter | MT 1060 |

|---|---|

| Max Sheet Size | 1060 × 760 mm |

| Min Sheet Size | 400 × 350 mm |

| Max Die-Cutting Area | 1050 × 750 mm |

| Max Stamping Depth | 4 mm |

| Max Speed | 6000 sheets/hour |

| Max Pressure | 320 tons |

| Paper/Board Thickness | 90–2000 g/m² |

| Foil Rolls Supported | Up to 3 simultaneous foils |

| Power Supply | 380V / 50Hz / 20 kW |

| Machine Dimensions (L×W×H) | 5900 × 2700 × 2200 mm |

| Net Weight | 12,500 kg |

Proper operation is essential for achieving high-quality die-cutting and stamping results while maintaining machine longevity.

Verify that the machine is level and all fasteners are secure.

Inspect the sheet stock for flatness, moisture, and surface quality.

Check foil rolls, cutting dies, and lubrication points.

Select sheet size, speed, and pressure on the HMI.

Adjust die-cutting and stamping depth according to material thickness.

For multi-color jobs, program registration points for precise alignment.

Place sheets into the feeder tray, ensuring smooth stacking.

Check foil roll tension and alignment for accurate stamping.

Run a small batch of sheets to verify registration, cutting depth, and foil transfer.

Adjust parameters if necessary before full-scale production.

Monitor output for alignment, foil adhesion, and embossing clarity.

Replace foil rolls or sheets as needed to maintain consistent quality.

Routine maintenance ensures long-term machine performance, precision, and reliability.

| Maintenance Frequency | Tasks |

|---|---|

| Daily | Clean dust and debris from feeders, rollers, and stamping areas; check lubrication levels; inspect for abnormal noises. |

| Weekly | Tighten bolts and fasteners; check foil tension; clean air filters; inspect rollers and belts. |

| Monthly | Calibrate pressure and registration sensors; inspect bearings, guide rails, and mechanical connections; verify safety system functionality. |

| Quarterly | Perform complete mechanical inspection; check electrical components; test servo motors and PLC performance; clean and oil moving parts. |

| Annually | Replace consumables (lubricants, filters, heating elements); full trial run for performance validation; update software if necessary. |

Use manufacturer-recommended oil for bearings and moving parts.

Check automatic lubrication systems daily and refill as needed.

Clean rollers and belts to remove adhesive residue and paper dust.

Inspect for wear or deformation and replace when necessary.

Clean cutting dies after each run to prevent residue build-up.

Store dies and foils in a dry environment to prevent corrosion.

Regularly calibrate registration, pressure, and temperature sensors to maintain production accuracy.

Test emergency stop buttons and interlocked doors before each production shift.

Inspect pneumatic lines for leaks and replace damaged components immediately.

Provide detailed training on HMI usage, safety procedures, and maintenance routines.

Encourage operators to document issues and maintenance performed for quality tracking.

The MT 1060 offers exceptional performance across multiple metrics, making it ideal for high-volume, high-quality production:

Precision: Micron-level registration ensures accurate die-cutting and foil stamping.

Speed: Capable of producing up to 6000 sheets per hour with consistent quality.

Flexibility: Handles a wide range of substrates and thicknesses, including specialty materials.

Durability: Heavy-duty frame and quality components reduce vibration and mechanical wear.

Automation: Reduces labor and manual adjustments, enhancing operational efficiency.

Safety: Integrated systems minimize risk and protect operators.

The MT 1060 is widely used in industries requiring premium finishing effects:

Luxury Packaging: Cosmetic boxes, wine bottles, gift packaging.

Commercial Printing: Book covers, brochures, certificates.

Specialty Products: Labels, embossed logos, promotional cards.

Material Compatibility: Paperboard, cardboard, laminated sheets, PVC, PET.

Its ability to integrate die-cutting and stamping into one automated process ensures consistent decorative quality and reduces production time.

Flat, level floor capable of supporting machine weight.

Adequate ventilation and low-dust environment.

Stable power supply (380V / 50Hz) with grounding.

Level the machine using adjustment screws.

Allow sufficient clearance around the machine for maintenance and operation.

Connect power and verify grounding.

Connect pneumatic lines and check for leaks.

Perform a trial run with sample sheets to verify registration, pressure, and speed.

Adjust parameters as needed before full production.

The MT 1060 Automatic Stamping and Die-Cutting Machine is a high-performance, versatile, and reliable solution for modern printing and packaging industries. With integrated die-cutting and stamping, servo-driven precision, and heavy-duty construction, it ensures consistent high-quality production while reducing labor and material waste.

Proper operation, routine maintenance, and adherence to safety protocols ensure long-term reliability, precision, and efficiency, making the MT 1060 an ideal investment for manufacturers seeking premium decorative finishes, operational efficiency, and long-term durability.

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

This website uses cookies to ensure you get the best experience on our website.