Technical Parameters

| MT 1050 Automatic Stamping And Die-Cutting Machine | |

| Model | MT 1050 Automatic Stamping And Die-Cutting Machine |

| Max.paper size | 1060×800mm |

| Min.paper size | 400×360mm (Option servo paper delivery 370× 270) |

| Max.die-cutting size | 1050×750mm |

| Die-cutting precision | ±0.075mm |

| Max.working pressure | 450T |

| Max.working Speed | 7500P/H |

| Air requirements | 0.6~0.8mp 0.36m³ |

| Paper thickness | White card/plastic sheet:0.1~1.5mm Grey board:<2.5mm Corrugated paper:<6mm |

| Gripper range | 3~8mm |

| Min distance between cutting line and plate edge | 15mm |

| Motor power | 15Kw |

| Heating power | 27.8Kw |

| Servo total power | 16Kw |

| Total power | 64Kw |

| Working power | 32Kw |

| Weight | 21T |

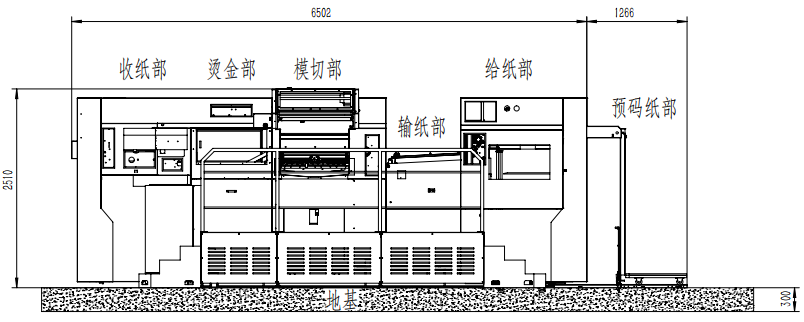

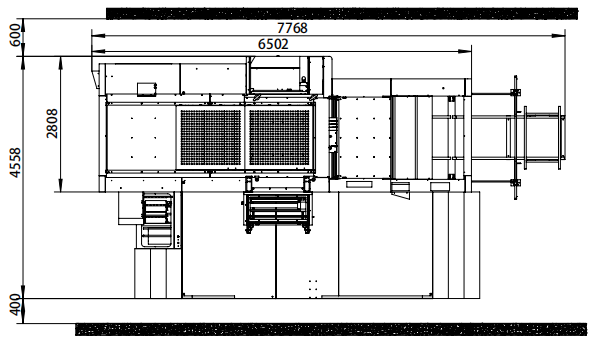

| Dimensions | 6502×2808×2510mm pedal width 1750mm |

Sketch

video

MT 1050 Automatic Stamping and Die-Cutting Machine

The MT 1050 Automatic Stamping and Die-Cutting Machine is a high-speed, high-precision post-press finishing solution engineered for modern printing and packaging industries. Designed for foil stamping, die-cutting, creasing, and embossing, it delivers exceptional performance, reliability, and production efficiency for manufacturers aiming for premium-quality packaging.

Built with advanced automation technology, the MT 1050 combines intelligent control, accurate registration, and powerful pressure capacity, ensuring every sheet is processed with consistent precision and smooth operation. It is widely used in luxury packaging, paperboard production, and commercial printing, helping enterprises achieve higher output, reduced waste, and superior decorative results.

The MT 1050 integrates foil stamping and die-cutting in one system, enabling multiple processes in a single pass. This significantly reduces manual handling, shortens setup time, and enhances production efficiency.

A cast-iron machine frame ensures maximum stability and minimal vibration during operation. The robust construction supports long-term, heavy-duty production while maintaining accurate pressure and alignment.

Equipped with a PLC control system and touch-screen HMI, operators can easily adjust pressure, temperature, and speed parameters, monitor real-time performance, and store multiple job settings for repeat orders.

The automatic sheet feeder with vacuum suction technology guarantees smooth feeding and precise positioning of each sheet. The delivery section neatly stacks finished products, minimizing operator intervention and improving workflow efficiency.

| Feature | Description / Benefit |

|---|---|

| High-Precision Stamping and Die-Cutting | Achieves excellent alignment accuracy for intricate designs and small tolerances |

| Heavy-Duty Construction | Stable frame ensures reliable performance at high speeds |

| Automatic Foil Feeding System | Optimizes foil use with programmable tension control |

| Servo Motor Registration | Guarantees accurate sheet positioning and reduces waste |

| Touch-Screen Interface | User-friendly operation and fast job setup |

| Multi-Zone Temperature Control | Ensures uniform heating and consistent foil transfer |

| Safety Protection System | Includes emergency stop, interlocking doors, and overload protection |

| Automatic Lubrication | Reduces wear and maintenance requirements |

| Model | MT 1050 |

|---|---|

| Max Sheet Size | 1050 × 750 mm |

| Min Sheet Size | 400 × 350 mm |

| Max Stamping Area | 1040 × 730 mm |

| Max Cutting Area | 1040 × 730 mm |

| Max Speed | 6000 sheets/hour |

| Max Pressure | 300 tons |

| Paper Thickness | 90 – 2000 g/m² |

| Temperature Range | 0 – 200°C |

| Power Supply | 380V / 50Hz / 18 kW |

| Machine Dimensions (L×W×H) | 5800 × 2500 × 2200 mm |

| Net Weight | Approx. 11,000 kg |

Specifications can be customized according to production needs.

The MT 1050 Automatic Stamping and Die-Cutting Machine is manufactured under strict quality control systems, following international industrial and safety standards to ensure durability, precision, and reliability in long-term use.

Each mechanical component—shafts, gears, bearings, and plates—undergoes dynamic balance testing and dimensional tolerance inspection to guarantee stable running at high speeds.

All electrical modules comply with CE and ISO electrical safety standards. Control panels, sensors, and servo systems are tested for overload protection, temperature accuracy, and response speed.

Pressure accuracy is verified using high-precision sensors, while heating plates are tested for uniform temperature distribution to ensure consistent foil transfer and cutting depth.

The MT 1050 is engineered for low-noise operation, meeting workplace environmental standards. Vibration is minimized through optimized mechanical balance and damping design.

Before delivery, every unit undergoes a 24-hour continuous operation test, simulating actual production conditions to verify operational stability, safety, and efficiency.

The MT 1050 is suitable for a wide variety of post-press finishing applications, providing luxurious visual and tactile effects on different packaging and printing materials.

Cosmetic boxes

Wine and liquor packaging

Food and beverage cartons

Pharmaceutical boxes

Gift packaging

Greeting cards

Certificates

Book covers

Brochures and invitations

Hot-stamped labels

Metallic foil logos

Embossed product branding

The machine’s adaptability to paperboard, cardboard, laminated paper, PET film, and synthetic substrates makes it a versatile tool for high-end product finishing.

Customer satisfaction and reliability are the core of the MT 1050 design and service philosophy. Every machine is backed by a comprehensive warranty and professional after-sales support.

Warranty Period: 12 months from the date of installation.

Coverage: Mechanical and electrical components (excluding consumables).

Consumables: Heating elements, foils, and lubrication oil are not included in the warranty.

Extended Warranty: Optional service contracts are available for extended coverage and preventive maintenance.

24-hour online technical support via email or video call.

On-site installation and operator training provided by professional engineers.

Remote troubleshooting and software updates through the control system.

We maintain a permanent inventory of genuine spare parts, ensuring quick replacement and minimal downtime for customers worldwide.

Routine maintenance services are available upon request, including calibration, lubrication checks, and part replacement, to ensure optimal long-term performance.

Proper maintenance ensures the MT 1050 maintains its precision, longevity, and efficiency.

Clean foil debris and paper dust from the work area.

Check pressure gauges and lubrication levels.

Ensure heating plates are clean and free of adhesive residue.

Tighten bolts and inspect pneumatic connections.

Clean or replace air filters.

Check foil feeding tension and alignment.

Calibrate temperature sensors and registration alignment.

Inspect belts, bearings, and rollers for wear.

Verify servo motor response and safety circuit integrity.

Note: Always power off and release mechanical pressure before performing maintenance.

The MT 1050 is built with multiple safety mechanisms to protect operators and ensure secure operation.

Safety Doors and Sensors: Automatic shutdown when doors are opened.

Emergency Stop Buttons: Placed at key points for quick response.

Overload Protection: Prevents mechanical damage from excess pressure.

Thermal Control Safety: Prevents overheating and foil damage.

Operator Training: Recommended for all users before production.

Following these safety procedures ensures a stable and accident-free working environment.

To meet global manufacturing standards, the MT 1050 is produced under certified quality systems:

| Standard / Certification | Description |

|---|---|

| ISO 9001:2015 | Quality Management System Certification |

| CE Certification | Conformity with European Safety Standards |

| RoHS Compliance | Environmentally friendly material compliance |

| Factory Inspection Report | Passed mechanical, electrical, and performance validation |

This strict adherence to international standards guarantees product reliability and customer confidence.

The MT-1050 is engineered to meet modern sustainability requirements. Its intelligent temperature control and servo-driven system reduce energy consumption and material waste, contributing to eco-friendly production.

Low Energy Consumption: Optimized heating zones reduce power loss.

Waste Reduction: Precision registration minimizes material waste.

Noise Control: Complies with industrial workplace standards.

To ensure safe transport and delivery, the MT 1050 is securely packed with anti-rust protection and shock-absorbing materials.

Fumigation-free wooden crate

Plastic film wrapping for dust and moisture protection

Labeled accessories and user manuals included

Standard lead time: 45–60 days after order confirmation

Optional sea or air freight depending on customer preference

Professional technicians provide on-site setup, calibration, and operational training to ensure seamless production startup.

Choosing the MT 1050 Automatic Stamping and Die-Cutting Machine offers tangible benefits for manufacturers:

High-speed production with minimal waste

Consistent and precise finishing quality

Reduced labor through automation

Long-term durability with minimal maintenance

Comprehensive global support network

The MT 1050 Automatic Stamping and Die-Cutting Machine represents a powerful solution for today’s high-end printing and packaging industry. Combining advanced technology, precision engineering, and intelligent automation, it ensures superior performance, efficiency, and aesthetic excellence.

From luxury packaging to commercial printing, the MT 1050 is the trusted choice for manufacturers seeking stable operation, perfect finishing effects, and long-term profitability.

With rigorous quality control, professional service, and global reliability, it continues to set the benchmark for modern die-cutting and stamping machinery.

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

This website uses cookies to ensure you get the best experience on our website.