Technical Parameters

| MP 1050 Fully Stripping And Die-Cutting Machine | |

| Model | MP-1050 Fully Stripping And Die-Cutting Machine |

| Max.paper size | 1060×800mm |

| Min.paper size | 400×360mm (Option servo paper delivery370× 270) |

| Max.die-cutting size | 1050×750mm |

| Die-cutting precision | ±0.075mm |

| Max.working pressure | 450T |

| Max.working speed | 8000P/H |

| Air requirements | 0.6~0.8mp 0.25m³ |

| Paper thickness | White card/plastic sheet:0.1~1.5mm Grey board:<2.5mm Corrugated paper:<6mm |

| Gripper range | 3~8mm |

| Min distance between cutting line and plate edge | 15mm |

| Motor power | 15Kw |

| Heating power | -- |

| Total power | 21Kw |

| Working power | 16.8Kw |

| Weight | 16.5T |

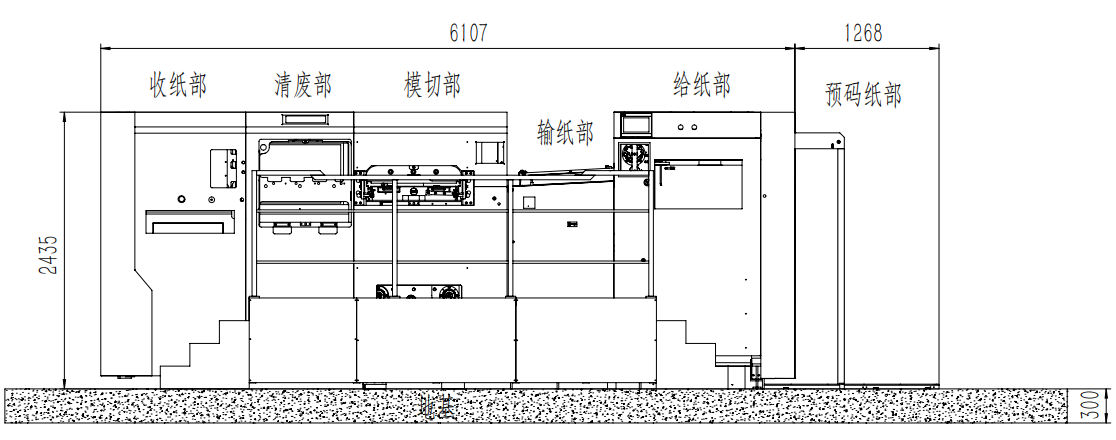

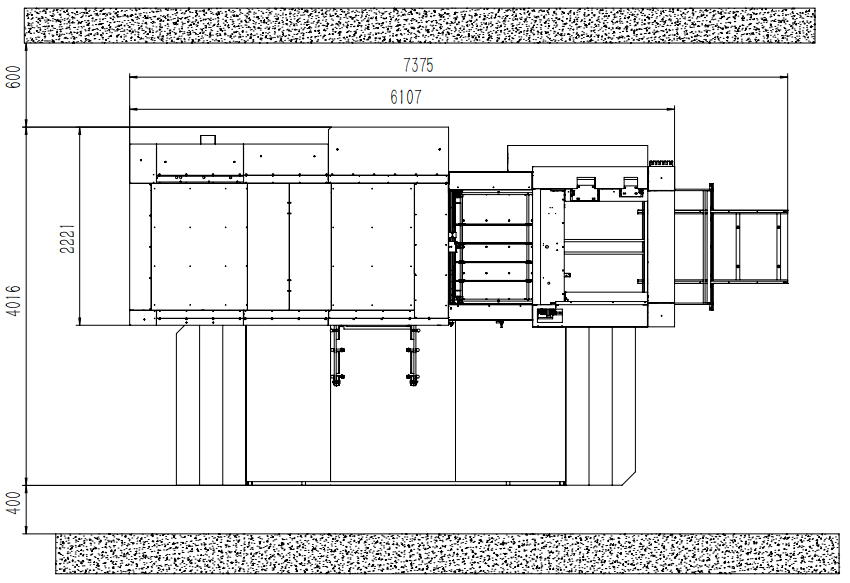

| Dimensions | 6107×2221×2435mm pedal width 1750mm |

Sketch

MP 1050 Fully Stripping And Die-Cutting Machine

The MP 1050 Fully Stripping And Die-Cutting Machine is a high-efficiency, precision-engineered solution for modern packaging and printing industries. Designed to handle folding cartons, paperboard packaging, labels, and specialty cardboard products, the MP 1050 integrates fully automatic stripping and high-accuracy die-cutting to deliver professional-quality, consistent finished products.

Equipped with a robust steel frame, intelligent PLC control system, and comprehensive safety features, this machine ensures smooth operation, reduces manual labor, and increases production efficiency. Its combination of precision, durability, and automation makes it ideal for both industrial-scale production and specialty packaging applications.

Fully Automatic Stripping System

Top and bottom stripping pins automatically remove waste.

Servo-controlled movement ensures precise alignment and clean sheets.

Quick-change stripping components allow rapid job transitions.

High-Precision Die-Cutting

Advanced pressure distribution system ensures ±0.1 mm cutting accuracy.

Reduces material waste and delivers professional-quality finishes.

Robust Construction

Reinforced steel frame minimizes vibration and improves operational stability.

Industrial-grade components enhance machine longevity.

User-Friendly Control

PLC system with HMI touchscreen simplifies operation and setup.

Multi-language interface accommodates global operators.

Memory function stores parameters for repeated production runs.

| Feature | Specification |

|---|---|

| Model | MP 1050 Fully Stripping And Die-Cutting Machine |

| Max Sheet Size | 1050 × 760 mm |

| Min Sheet Size | 450 × 400 mm |

| Maximum Die-Cutting Pressure | 300 tons |

| Die-Cutting Accuracy | ±0.1 mm |

| Maximum Production Speed | Up to 6,500 sheets/hour |

| Stripping System | Fully automatic top and bottom stripping |

| Feeding System | Front-edge feeder with air-assist |

| Control System | PLC with HMI touchscreen |

| Safety Features | Emergency stop, photoelectric sensors, overload protection |

| Applications | Folding cartons, cardboard packaging, labels, paperboard products |

A structured maintenance plan is essential to ensure long-term performance and reliability of the MP 1050.

Clean feeders, die-cutting plates, and stripping pins to remove dust and debris.

Check lubrication points and apply recommended oil.

Verify air pressure in feeder and stripping nozzles.

Inspect safety sensors and emergency stops for proper function.

Inspect belt and chain tension; adjust as needed.

Lubricate bearings, guide rails, and moving joints.

Tighten any loose mechanical fasteners.

Inspect stripping system alignment and functionality.

Examine die-cutting plates and embossing tools for wear or deformation.

Test PLC and HMI touchscreen responsiveness.

Inspect electrical wiring and connections for corrosion or looseness.

Replace lubricants and hydraulic fluids according to manufacturer guidelines.

Conduct a full system calibration, including die pressure and sheet alignment.

Arrange for certified service inspection by a qualified technician.

Proper cleaning ensures optimal performance, reduces material contamination, and prolongs component life.

Daily Cleaning

Remove paper dust from feeders, die-cutting plates, and stripping pins using a soft brush or vacuum.

Wipe control panels and touchscreens with a dry microfiber cloth.

Weekly Cleaning

Clean guide rails and moving parts with non-corrosive cleaning solutions.

Inspect air nozzles and clean or replace as needed.

Monthly Deep Cleaning

Disassemble and clean die-cutting plates and stripping components.

Inspect for wear or deformation and replace damaged parts.

Note: Avoid using water or corrosive chemicals on electrical components and steel parts.

The MP 1050 is shipped with protective packaging to ensure safe transport and easy installation.

| Item | Description |

|---|---|

| Outer Packaging | Wooden crate with shock absorption and waterproof wrap |

| Machine Protection | Anti-corrosion oil coating on all exposed metal surfaces |

| Accessories | Spare parts, tool kit, instruction manual, and warranty card |

| Shipping Options | Sea freight, air freight, or land transport, with custom support |

| Assembly Instructions | Detailed diagrams and step-by-step guide included |

Note: Operators should carefully inspect the machine and accessories upon arrival to ensure all components are intact before installation.

| Component | Description |

|---|---|

| Frame | Reinforced steel structure for stability |

| Die-Cutting Plate | High-precision cutting plates for consistent results |

| Stripping Pins | Top and bottom pins for automatic waste removal |

| Feeder System | Front-edge feeder with air-assist nozzles |

| Control System | PLC with HMI touchscreen interface |

| Safety Devices | Emergency stop buttons, photoelectric sensors, overload protection |

| Hydraulic System | Pressure control for die-cutting and stripping |

| Delivery Section | Stacking and collection system for finished sheets |

| Tool Kit | Wrenches, screwdrivers, and spare bolts for maintenance |

| Spare Parts | Extra belts, bearings, and lubrication supplies |

Material Selection: Ensure sheets are within recommended thickness and density for optimal results.

Warm-Up Procedure: Allow hydraulic and control systems to stabilize for 10–15 minutes before full-speed operation.

Parameter Storage: Use the PLC memory function for repeated jobs to save setup time.

Operator Training: All operators should receive training on setup, safety, and troubleshooting.

Safety Compliance: Always wear PPE and avoid bypassing safety interlocks.

The MP 1050 Fully Stripping And Die-Cutting Machine is ideal for:

Folding Cartons: Packaging for consumer goods, pharmaceuticals, and food.

Cardboard Packaging: Efficient large-volume production.

Labels and Paperboard Displays: Precision die-cutting for retail and marketing materials.

Specialty Products: Custom cardboard or laminated sheets for branding and luxury packaging.

Its combination of fully automatic stripping, precise die-cutting, and robust construction makes it suitable for both small-scale specialty production and industrial-scale operations.

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

This website uses cookies to ensure you get the best experience on our website.