Technical Parameters

| SQ820L Automatic Stripping And Die-Cutting Machine | |

| Model | SQ-820L Automatic Stripping And Die-Cutting Machine |

| Max.paper size | 830×570mm |

| Min.paper size | 300×270mm |

| Max.die-cutting size | 820×560mm |

| Die-cutting precision | ±0.075mm |

| Max.working pressure | 320T |

| Max.working Speed | 8000P/H |

| Air requirements | 0.6~0.8Mp 0.36m³ |

| Paper thickness | White card/plastic sheet:0.1~1.5mm Grey board:<2.5mm Corrugated paper:<4mm |

| Gripper range | 3~7mm |

| The distance between the first cutting line and the template | 15mm |

| Motor power | 5.5Kw |

| Total Power | 11Kw |

| Working power | 8Kw |

| Weight | 11T |

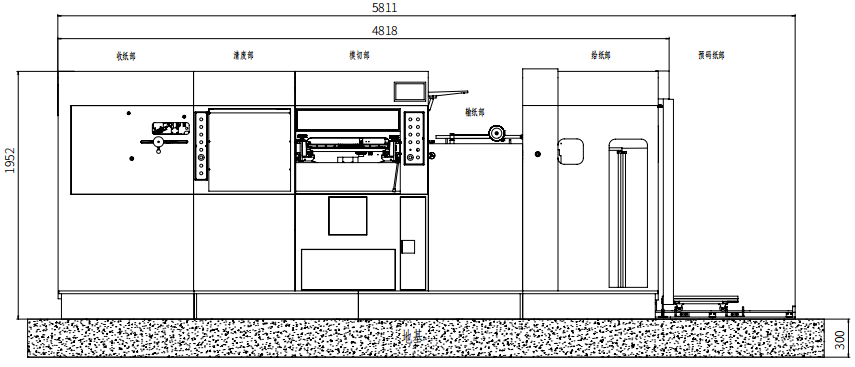

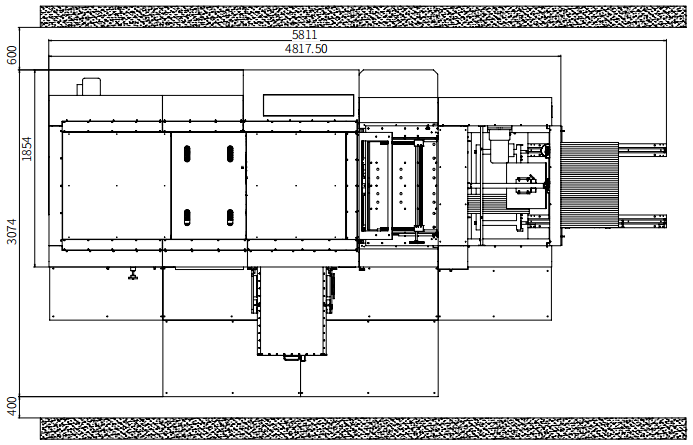

| Dimensions | 4818×1854×1952mm pedal width 1220mm(Optional) |

Sketch

SQ 820L Automatic Stripping and Die-Cutting Machine: Comprehensive Guide

The SQ 820L Automatic Stripping and Die-Cutting Machine is a state-of-the-art industrial solution designed for high-volume paper, cardboard, and packaging production. This machine combines advanced automation with precision engineering to enhance productivity, minimize waste, and ensure consistent quality. Suitable for printing houses, packaging manufacturers, and die-cutting workshops, the SQ 820L is an ideal choice for businesses aiming to streamline production while maintaining high-quality output.

Fully Automated Operation: Integrates automatic feeding, die-cutting, and stripping, reducing manual intervention.

High Precision: Ensures consistent cutting and stripping accuracy across various material types.

Durable Construction: Heavy-duty frame and high-quality components for long-term reliability.

User-Friendly Interface: Touchscreen control panel simplifies operation and reduces learning curve.

Energy Efficiency: Optimized power usage for cost-effective production.

| Feature | Description |

|---|---|

| Machine Type | Automatic Stripping and Die-Cutting Machine |

| Model | SQ 820L |

| Material Compatibility | Paper, Cardboard, Corrugated Board |

| Maximum Sheet Size | 820 mm x 1200 mm |

| Cutting Speed | Up to 5000 sheets/hour |

| Power Supply | 380V / 50Hz |

| Control System | PLC with touchscreen interface |

| Safety Mechanisms | Emergency stop, safety guards, overload protection |

Ensuring consistent quality is vital for high-volume die-cutting operations. The SQ 820L incorporates multiple quality control measures:

Precision Calibration: Every unit is factory-calibrated for accurate cutting and stripping.

Material Inspection: Incoming materials are verified for thickness and consistency.

Operational Testing: Machines undergo full-cycle tests before shipping.

ISO Compliance: Manufactured according to international standards to ensure reliability and safety.

| Inspection Stage | Key Checks |

|---|---|

| Pre-Production | Sheet alignment, die accuracy |

| Mid-Production | Cutting consistency, stripping quality |

| Post-Production | Final product inspection, machine calibration |

Investing in the SQ 820L comes with professional support to ensure seamless operation:

Installation and Training: Certified technicians provide on-site installation and operator training.

Technical Support: 24/7 remote support and troubleshooting assistance.

Spare Parts Availability: OEM parts supplied promptly to minimize downtime.

Maintenance Guidance: Detailed maintenance manuals and preventive schedules included.

Pro Tip: Routine maintenance, such as lubrication of moving parts and blade inspection, can significantly extend machine life and maintain cutting precision.

Proper shipping and handling are critical to avoid damage and ensure the machine operates optimally upon delivery.

Packaging: Machine is secured in reinforced crates with protective padding.

Handling: Use forklifts or cranes with adequate weight capacity; avoid tilting the machine excessively.

Environmental Conditions: Keep machine dry and avoid exposure to extreme temperatures during transport.

Unpacking: Inspect for visible damage and verify that all components and accessories are included.

| Transport Step | Recommended Practice |

|---|---|

| Lifting | Use designated lifting points only |

| Securing | Fasten to transport vehicle to prevent shifting |

| Storage | Dry, covered, and ventilated area |

| Pre-Operation Check | Inspect mechanical parts and electrical connections |

Understanding potential issues helps minimize downtime. Below are common causes and remedies for the SQ 820L:

| Fault | Possible Cause | Recommended Solution |

|---|---|---|

| Machine does not start | Power supply issues, emergency stop activated | Check power line, reset emergency stop |

| Cutting misalignment | Die not properly installed, calibration error | Reinstall die, perform calibration |

| Stripping incomplete | Stripping plate worn, material thickness mismatch | Replace plate, adjust settings |

| Excessive noise during operation | Loose components, inadequate lubrication | Tighten screws, lubricate moving parts |

| Frequent jams | Improper sheet feeding, debris on cutting bed | Adjust feeder, clean cutting area |

Schedule regular inspections for blade sharpness and mechanical wear.

Keep the die-cutting area clean and free from dust or scraps.

Train operators to follow standard operating procedures strictly.

Material Preparation: Ensure sheets are flat and of uniform thickness before feeding.

Loading: Properly align sheets to prevent misfeeds.

Monitoring: Continuously observe machine operation for early detection of abnormalities.

Documentation: Maintain logs of maintenance, repairs, and production output for analysis.

Enhanced Productivity: High-speed automatic operation increases throughput.

Reduced Waste: Accurate stripping and die-cutting minimize material loss.

Consistency and Quality: Every sheet is processed with precision.

Operational Safety: Built-in safeguards protect operators.

Cost-Effective: Low maintenance and energy-efficient design reduce overall production costs.

The SQ 820L Automatic Stripping and Die-Cutting Machine is an indispensable tool for modern packaging and printing industries. Combining high precision, durability, and automation, it addresses the critical needs of high-volume production while maintaining safety and quality standards. With comprehensive after-sales support, clear operational guidance, and detailed maintenance protocols, businesses can confidently integrate the SQ 820L into their production lines, optimizing efficiency and ROI.

Investing in the SQ 820L ensures consistent performance, reduced material waste, and streamlined operations, making it a reliable choice for professional manufacturers worldwide.

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

This website uses cookies to ensure you get the best experience on our website.