Technical Parameters

| MY 1520 Automatic Die-Cutting Machine | |

| Model | MY-1520 Automatic Die-Cutting Machine |

| Max.paper size | 1520×1120mm |

| Min.paper size | 450×450mm |

| Max.die-cutting size | 1500×1110mm |

| Die-cutting precision | ±0.3mm |

| Max.working pressure | 300T |

| Max.working speed | 5500P/H |

| Air requirementsSpeed | 0.6~0.8mp 0.25m³ |

| Paper thickness | Corrugated paper≤8mm |

| Gripper rangespeed | 12mm |

| Motor power | 15Kw |

| Total power | 27Kw |

| Working power | 24Kw |

| Weight | 19T |

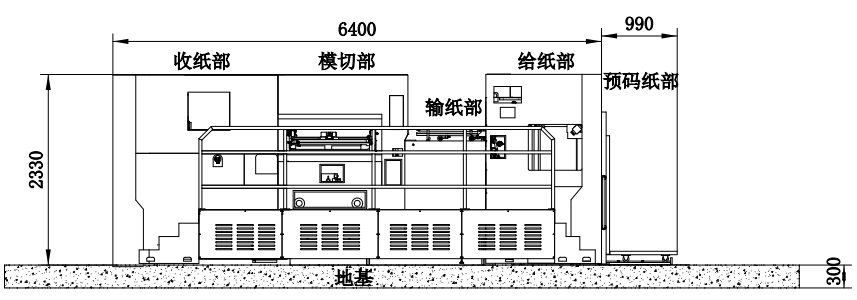

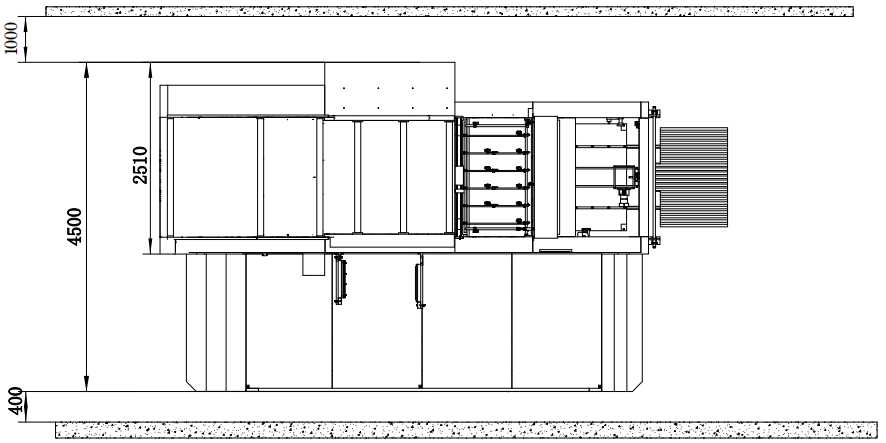

| DimensionsDimensions | 7390×4500×2330mm |

| Optional servo upper paper feeding mode:1520 paper feeding size 400×400MM | |

Sketch

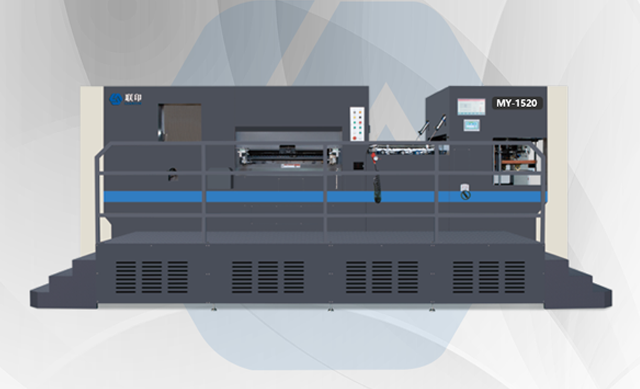

MY 1520 Automatic Deep Embossing and Die-Cutting Machine: High-Precision Industrial Solution

The MY 1520 Automatic Deep Embossing and Die-Cutting Machine is a cutting-edge industrial machine designed for precision embossing and die-cutting of paper, cardboard, plastics, and specialty materials. Combining automation, high-precision mechanics, and eco-friendly design, the MY 1520 is ideal for packaging, printing, decorative, and high-end production industries.

Fully Automatic Operation: Integrated feeding, embossing, die-cutting, and stacking functions reduce labor and enhance production efficiency.

Deep Embossing Capability: Supports intricate designs and high-relief embossing for premium packaging and decorative products.

Precision Die-Cutting: Accurate registration ensures consistent results with minimal material waste.

User-Friendly Interface: Touchscreen control panel with programmable settings and diagnostic tools for easy operation.

Energy Efficiency: Optimized motor and mechanical systems reduce electricity consumption without sacrificing performance.

Durable Construction: Heavy-duty steel frame ensures long-term reliability in high-volume production environments.

The MY 1520 is designed with a focus on precision, automation, and environmental responsibility.

Automation: Reduces manual intervention and increases throughput.

Accuracy: High-precision motion control ensures perfect registration for die-cut and embossed designs.

Sustainability: Incorporates energy-efficient motors, low-noise operation, and recyclable components.

Maintenance-Friendly Design: Modular components and accessible layout simplify maintenance and minimize downtime.

The MY 1520 meets global environmental and safety standards, ensuring responsible manufacturing practices:

| Standard | Description |

|---|---|

| CE | Complies with EU machinery safety, health, and environmental requirements |

| RoHS | Restriction of hazardous substances for eco-friendly production |

| ISO 14001 | Environmental management system compliance for sustainable operations |

| Energy Star | High energy efficiency for industrial machinery |

These certifications guarantee that the MY 1520 operates safely while minimizing environmental impact.

Proper installation is essential for optimal performance and long-term durability of the MY 1520:

Site Preparation: Ensure a stable, level floor capable of supporting the machine’s weight. Maintain sufficient space for operation and maintenance.

Power Supply: Connect to a stable 380V, 50/60Hz, 3-phase power supply. Ensure proper grounding and compliance with local electrical codes.

Machine Placement: Position the machine in a vibration-free area to maintain embossing and cutting accuracy.

Air Supply: Connect to a regulated compressed air source for pneumatic operations.

Initial Testing: Run a test cycle with sample material to verify proper feeding, embossing, die-cutting, and stacking. Adjust settings as needed.

Operator Training: Ensure personnel are trained in safe operation, emergency procedures, and routine maintenance.

The MY 1520 is equipped with high-quality components to ensure reliability and precision:

| Component | Description |

|---|---|

| Servo Motor System | Precision motion control for embossing and die-cutting |

| Feeding Unit | Automatic feeding with adjustable guides for various materials |

| Embossing Unit | High-relief embossing mechanism for deep and intricate designs |

| Die-Cutting Unit | Heavy-duty die-cutting with precise registration |

| Control Panel | Touchscreen HMI with programmable settings and error diagnostics |

| Stacking & Delivery | Automated stacking system with adjustable height and alignment |

| Safety Guards | Protective covers, sensors, and emergency stop buttons |

| Pneumatic System | Reliable air pressure system for smooth embossing and cutting |

| Specification | MY 1520 Details |

|---|---|

| Max Embossing Area | 1520 mm × 1020 mm |

| Max Material Thickness | 10 mm (depending on material type) |

| Embossing Speed | 1,500–3,000 sheets/hour |

| Power Supply | 380V, 50/60Hz, 3-phase |

| Machine Dimensions | 4,500 × 2,000 × 2,200 mm |

| Machine Weight | 4,500 kg |

| Control System | PLC + Touchscreen HMI |

| Safety Features | Emergency stops, protective covers, sensors |

The MY 1520 adheres to rigorous quality control standards to ensure reliability and performance:

Incoming Material Inspection: All critical components undergo inspection before assembly.

Precision Calibration: Servo motors, embossing, and die-cutting units are calibrated for accuracy.

Performance Testing: Each unit is run under simulated production conditions to verify speed, alignment, and reliability.

Safety Compliance Check: All safety devices, emergency stops, and sensors are tested according to international standards.

Final Quality Audit: Complete machine inspection before delivery to ensure defect-free operation.

The MY 1520 Automatic Deep Embossing and Die-Cutting Machine is suitable for:

Packaging Industry: Premium cartons, boxes, and decorative packaging.

Printing Industry: High-quality embossed labels, stickers, and promotional materials.

Stationery Manufacturing: Folders, notebooks, and customized paper products.

Decorative Products: Specialty paper, laminates, and luxury packaging materials.

Its versatility makes it an essential solution for high-volume, high-precision production lines.

Enhanced Productivity: Fully automated operation accelerates production cycles.

Consistent Quality: Deep embossing and precise die-cutting ensure uniform results.

Reduced Costs: Minimizes labor, energy consumption, and material waste.

Durable & Reliable: Heavy-duty construction ensures long-term operation with minimal maintenance.

Eco-Friendly Operation: Energy-efficient motors and recyclable components support sustainable manufacturing.

The MY 1520 Automatic Deep Embossing and Die-Cutting Machine combines automation, precision, and environmental responsibility, making it a top choice for modern manufacturing. Certified to international quality and safety standards, the machine ensures consistent, high-quality output while reducing labor and operational costs. Its advanced design, durable construction, and eco-conscious features make it suitable for high-end packaging, printing, and decorative product industries worldwide.

Investing in the MY 1520 means faster production, superior aesthetics, lower waste, and enhanced efficiency—making it an indispensable solution for industrial embossing and die-cutting needs.

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

This website uses cookies to ensure you get the best experience on our website.