Technical Parameters

| MT 1060S Automatic deep embossing and hot stamping machine | |

| Model | MT 1060S Automatic Deep Embossing and Hot Stamping Machine |

| Max.paper size | 1080×800mm |

| Min.paper size | 400×360mm (Option servo paper delivery 370×270) |

| Max.die-cutting size | 1070×770mm |

| Die-cutting precision | ±0.09mm |

| Max.working pressure | 680T |

| Max.working Speed | 7200P/H |

| Air requirements | 0.6~0.8mp 0.36m³ |

| Paper thickness | White card/plastic sheet:0.1~1.5mm Grey board:<3mm Corrugated paper:<6mm |

| Gripper range | 3~8mm |

| Motor power | 17Kw |

| Heating power | 21.6Kw |

| Servo total power | 13.9Kw |

| Total power | 58.5Kw |

| Working power | 33Kw |

| Weight | 20T |

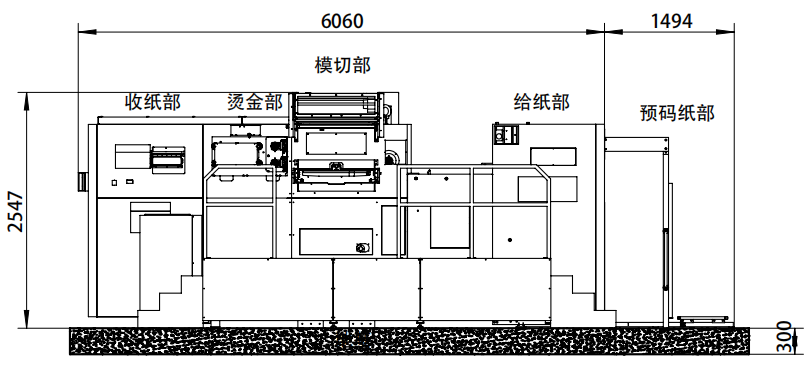

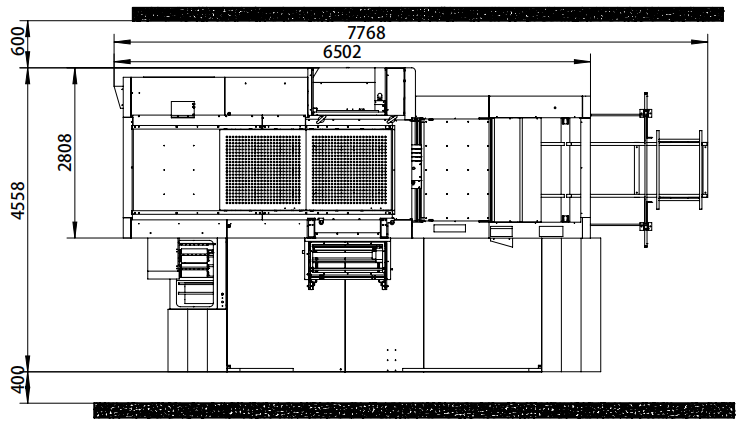

| DimensionsDimensions | 6060×2808×2547mm pedal width 1750 |

Sketch

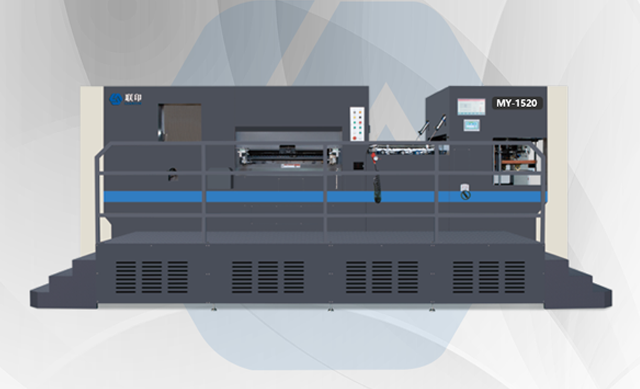

MT 1060S Automatic deep embossing and hot stamping machine

The MT 1060S Automatic Deep Embossing and Hot Stamping Machine is a high-precision post-press finishing solution designed for luxury packaging and decorative printing industries. It combines deep embossing and hot foil stamping in a single automated system, providing unmatched accuracy, speed, and consistency.

With an intelligent servo-driven control system, multi-zone temperature management, and a heavy-duty frame, the MT 1060S is ideal for creating premium textures, metallic foil finishes, and intricate embossed patterns on paperboard, cardboard, laminated sheets, and other high-end substrates.

This machine is widely used for cosmetic boxes, wine and gift packaging, book covers, and promotional paper products, helping manufacturers achieve high-quality decorative effects with minimal manual intervention.

The MT 1060S is engineered to accommodate a wide range of materials commonly used in premium packaging.

| Material Type | Recommended Thickness | Key Considerations |

|---|---|---|

| Paperboard | 250–1500 g/m² | Ensure smooth, dry surface for optimal foil adhesion |

| Cardboard | 300–2000 g/m² | Avoid warped or uneven boards to maintain embossing quality |

| Laminated Paper | 200–1200 g/m² | Compatible with hot stamping; check lamination tolerance |

| Synthetic Sheets (PVC/PET) | 100–500 μm | Requires precise temperature control to prevent warping |

| Specialty Coated Sheets | 150–1000 g/m² | Adjust temperature and pressure based on coating type |

Note: Testing on sample sheets is recommended to ensure optimal foil transfer and embossing depth.

The MT 1060S supports multi-color foil stamping, making it versatile for different designs and packaging effects.

The MT 1060S offers several distinct advantages over traditional finishing machines:

Combining embossing and hot stamping in a single pass reduces manual handling and improves production efficiency, minimizing alignment errors.

Servo-driven sheet feeding ensures micron-level alignment, enabling precise registration even for complex patterns or multi-color foil applications.

The heating system is divided into multiple zones, allowing uniform temperature distribution and consistent foil transfer across the entire sheet.

Intelligent foil unwinding, tensioning, and rewinding reduces waste and ensures smooth feeding, especially for long production runs.

The robust cast-iron frame minimizes vibration and mechanical wear, guaranteeing long-term stability and consistent embossing depth.

A touch-screen HMI (Human-Machine Interface) allows operators to adjust settings for temperature, pressure, sheet size, and feeding speed quickly and efficiently.

Equipped with emergency stop buttons, safety doors with sensors, and overload protection, the MT 1060S ensures operator safety and reduces machine downtime.

| Parameter | MT 1060S |

|---|---|

| Maximum Sheet Size | 1060 × 760 mm |

| Minimum Sheet Size | 400 × 350 mm |

| Maximum Stamping Area | 1050 × 750 mm |

| Maximum Embossing Depth | 4 mm |

| Maximum Speed | 6000 sheets/hour |

| Max Pressure | 320 tons |

| Temperature Range | 0–200°C |

| Paper/Board Thickness | 90–2000 g/m² |

| Foil Rolls Supported | Up to 3 simultaneous foils |

| Power Supply | 380V / 50Hz / 20 kW |

| Machine Dimensions (L×W×H) | 5900 × 2700 × 2200 mm |

| Net Weight | Approx. 12,500 kg |

Specifications may vary slightly depending on customization and optional features.

Proper installation is crucial to ensure safe operation and long-term performance of the MT 1060S.

Level floor with sufficient load-bearing capacity.

Adequate ventilation and dust-free environment.

Proper electrical supply (380V / 50Hz) with stable grounding.

Space allowance for operation and maintenance (recommended 1.5 m clearance around the machine).

Remove protective packaging carefully.

Check for shipping damage and verify all components are included.

Inspect lubrication points and add recommended oil if needed.

Place the machine on a flat, stable surface.

Use leveling screws to adjust and ensure horizontal alignment.

Verify that the feeding and delivery sections are aligned correctly.

Connect the machine to the dedicated power supply.

Verify grounding and electrical connections.

Turn on the control panel and test sensors, emergency stops, and servo motors.

Perform a trial run with sample sheets.

Adjust pressure, temperature, and foil feeding parameters based on material.

Observe foil transfer and embossing depth, making fine adjustments as needed.

Train operators on HMI operation, safety procedures, and maintenance routines.

Provide manuals and standard operating procedures for reference.

Quality assurance is central to the MT 1060S manufacturing process:

All sheets and foils are tested for adhesion, thickness, and surface finish to ensure compatibility with embossing and stamping.

Vibration test: Ensures minimal vibration at maximum speed.

Alignment check: Confirms precise registration across multiple sheets.

Pressure calibration: Guarantees uniform embossing depth.

Safety interlocks, PLC control, and HMI functions are fully tested.

Temperature and pressure sensors calibrated to ensure repeatable accuracy.

Continuous operation trial (8–24 hours) to verify stability.

Observation of foil transfer quality, embossing clarity, and cutting precision.

CE Certification ensures compliance with European safety standards.

ISO 9001:2015 certified manufacturing ensures quality management.

RoHS compliant components guarantee environmental friendliness.

Proper maintenance extends machine life and maintains quality output.

Remove paper dust and foil debris from work area.

Check and refill automatic lubrication system.

Inspect heating plates and clean if needed.

Check all fasteners and tighten bolts.

Clean air filters and check pneumatic lines.

Inspect foil rollers for smooth rotation and tension adjustment.

Calibrate temperature and pressure sensors.

Inspect bearings, belts, and guide rails for wear.

Test safety systems, including emergency stops and door sensors.

Complete inspection of mechanical, electrical, and pneumatic systems.

Replace consumables such as oil, filters, and heating elements.

Perform a full trial run to verify machine performance.

Safety Reminder: Always disconnect power before maintenance or adjustments.

The MT 1060S is suitable for a wide range of post-press decorative applications:

Luxury Packaging: Cosmetic boxes, wine boxes, gift boxes

Commercial Printing: Certificates, book covers, brochures

Specialty Products: Labels, embossed logos, promotional cards

Material Compatibility: Paperboard, cardboard, laminated sheets, synthetic substrates

Its capability to combine deep embossing with foil stamping creates elegant tactile and visual effects, enhancing brand identity and product value.

Increased Efficiency: Multi-process integration reduces setup and handling time.

High Precision: Servo-driven registration ensures perfect alignment and consistency.

Cost Savings: Reduced foil and material waste through intelligent tension control.

User-Friendly Operation: Touch-screen interface simplifies machine control.

Reliable Performance: Heavy-duty construction ensures long-term stability.

Safe Production: Integrated safety features protect operators and prevent damage.

Fumigation-free wooden crates with protective foam padding.

Plastic film wrapping for moisture and dust protection.

All accessories, manuals, and toolkits included.

Lead time: 45–60 days after order confirmation.

Optional sea or air freight depending on customer requirements.

24/7 online technical support.

On-site installation and training by professional engineers.

Spare parts availability for long-term support.

12-month warranty covering mechanical and electrical components.

The MT 1060S Automatic Deep Embossing and Hot Stamping Machine is a versatile, high-precision solution for modern packaging and printing industries. With integrated embossing and foil stamping, intelligent automation, and heavy-duty construction, it delivers exceptional decorative quality, operational efficiency, and long-term reliability.

Whether producing luxury packaging, high-end labels, or specialty paper products, the MT 1060S ensures every sheet meets exacting quality standards while maximizing productivity and minimizing waste. It is the ultimate choice for manufacturers seeking precision, efficiency, and superior decorative finishes in a single, automated machine.

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

This website uses cookies to ensure you get the best experience on our website.