Technical Parameters

| MY 1050S Automatic Die-Cutting Deep Embossing Machine | |

| Model | MY-1050S Automatic Die-Cutting Deep Embossing Machine |

| Max.paper size | 1060×800mm |

| Min.paper size | 400×360mm (Option servo paper delivery 370× 270) |

| Max.die-cutting size | 1050×750 |

| Die-cutting precision | ±0.075mm |

| Max.working pressure | 750T |

| Max.working speed | 8000P/H |

| Air requirementsSpeed | 0.6~0.8mp 0.25m³ |

| Paper thickness | White card/plastic sheet:0.1~1.5mm Grey board:<3mm Corrugated paper:<6mm |

| Gripper rangespeed | 3~8mm |

| Min distance between cutting line and plate edge | 15mm |

| Motor power | 18.5Kw |

| Heating power | 27.8Kw |

| Total power | 52Kw |

| Working power | 30Kw |

| Weight | 18T |

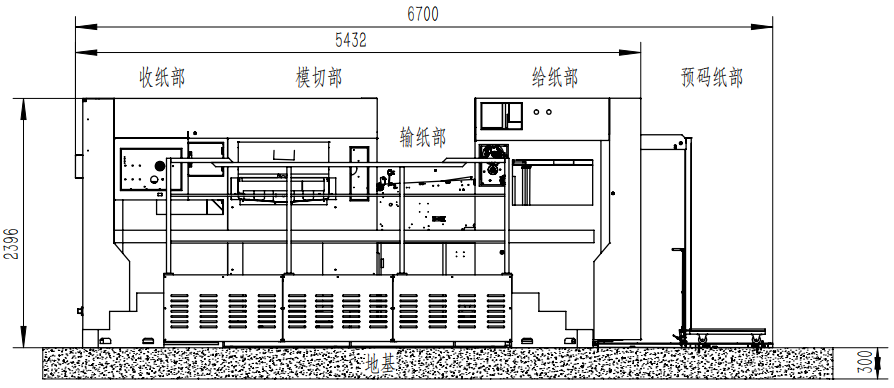

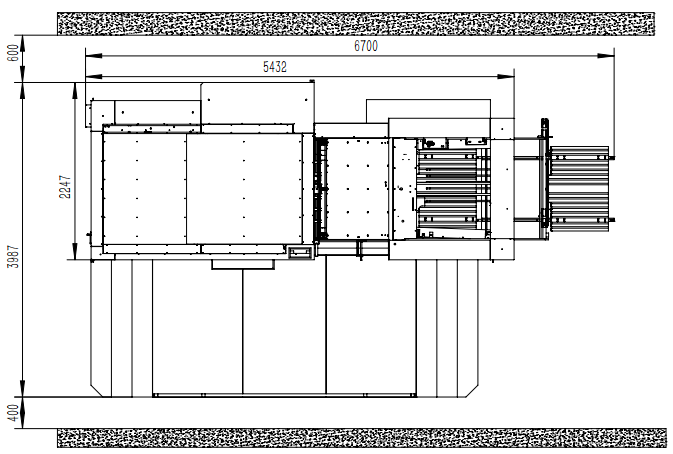

| DimensionsDimensions | 5432×2247×2396mm pedal width 1750mm |

Sketch

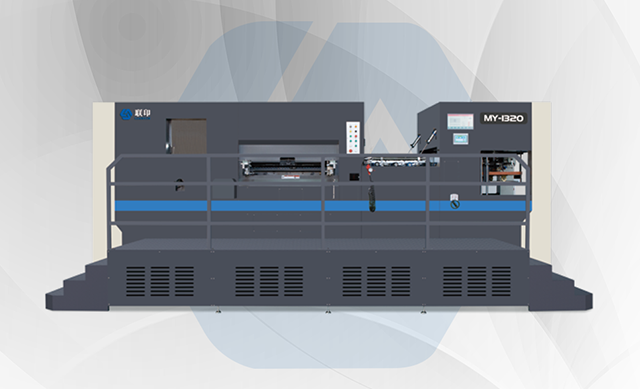

MY 1050S Automatic Die-Cutting Deep Embossing Machine: High-Precision Industrial Solution

The MY 1050S Automatic Die-Cutting Deep Embossing Machine is a state-of-the-art industrial solution engineered for high-precision die-cutting and deep embossing of paper, cardboard, plastics, and laminated materials. Combining advanced automation, robust design, and intelligent control systems, the MY 1050S is ideal for packaging, printing, label manufacturing, and decorative product industries.

Fully Automated Operation: Integrated feeding, die-cutting, deep embossing, and stacking functions reduce manual labor and improve production efficiency.

High-Precision Embossing: Supports intricate and high-relief embossing for premium packaging and decorative applications.

Versatile Die-Cutting: Compatible with cardboard, paper, PVC, PET, and laminated sheets.

User-Friendly Interface: Touchscreen HMI with programmable settings, diagnostics, and operational guides.

Durable Construction: Heavy-duty steel frame ensures long-term reliability in high-volume industrial environments.

Energy Efficient: Optimized motors and control systems reduce power consumption while maintaining performance.

The MY 1050S integrates multiple industrial processes into a single, high-performance machine:

| Function | Description |

|---|---|

| Die-Cutting | Accurate cutting and shaping of paper, cardboard, plastics, and laminates |

| Deep Embossing | High-relief embossing for luxury packaging and decorative designs |

| Automatic Feeding | Continuous feeding with adjustable guides for different material thicknesses |

| Stacking & Delivery | Automated stacking system with height and alignment adjustment |

| Registration System | Ensures precise alignment between die-cut and embossing operations |

| Safety Features | Emergency stops, protective covers, and sensors for operator safety |

| Specification | MY 1050S Details |

|---|---|

| Max Die-Cutting Area | 1050 mm × 750 mm |

| Max Material Thickness | 8 mm (depending on material type) |

| Embossing Depth | Up to 3 mm (depending on material) |

| Die-Cutting Speed | 1,000–2,000 sheets/hour |

| Embossing Speed | 800–1,500 sheets/hour |

| Power Supply | 380V, 50/60Hz, 3-phase |

| Machine Dimensions | 3,100 × 1,700 × 1,900 mm |

| Machine Weight | 2,700 kg |

| Control System | PLC + Touchscreen HMI |

| Safety Features | Emergency stops, protective covers, sensors |

The MY 1050S is manufactured and tested according to rigorous quality control procedures to ensure reliable and safe operation:

Incoming Component Inspection: Verify dimensional accuracy, material quality, and functional integrity of critical parts.

Assembly Inspection: Each component is carefully assembled and tested for mechanical precision.

Operational Testing: Machine is run with sample materials to check die-cutting accuracy, embossing quality, and alignment.

Electrical & Control Check: Verify PLC programming, HMI interface, and sensor functionality.

Final Quality Audit: Comprehensive inspection before shipment to guarantee defect-free operation.

Our technical service ensures smooth installation and operation:

Installation Assistance: Professional technicians provide guidance on machine placement, leveling, and connection to power and air supply.

Training for Operators: Detailed operational training is provided for safe and efficient use.

Remote Support: Troubleshooting and guidance via phone, video call, or online support.

Spare Parts Supply: Original spare parts are guaranteed for 5 years to ensure minimal downtime.

Proper fault detection and repair are crucial for maintaining machine performance:

| Fault | Possible Cause | Recommended Action |

|---|---|---|

| Machine won’t start | Power supply issue or emergency stop activated | Check main power, reset emergency stops, verify electrical connections |

| Irregular cutting or embossing | Misalignment or worn die | Re-align die, replace worn components |

| Material jams | Feed tray misalignment or debris | Clear jam, adjust feed guides, clean feeding system |

| Inconsistent embossing depth | Pressure or material thickness setting incorrect | Adjust pressure settings, verify material thickness |

Daily Maintenance:

Clean feeding, die-cutting, and embossing areas.

Inspect rollers, belts, and moving parts.

Lubricate bearings and gears according to guidelines.

Weekly Maintenance:

Check die alignment and registration accuracy.

Inspect pneumatic and hydraulic systems.

Test emergency stops and sensor functions.

Monthly Maintenance:

Conduct full calibration of die-cutting and embossing units.

Inspect electrical connections and control panel performance.

Tighten bolts and verify mechanical integrity.

Annual Maintenance:

Replace worn parts such as belts, rollers, and pneumatic hoses.

Inspect servo motors and control systems.

Update software and firmware as necessary.

Tips for Maintenance:

Use only manufacturer-approved lubricants and cleaning agents.

Maintain a clean and dry environment to prevent corrosion and dust accumulation.

Keep a detailed log of all maintenance activities and repairs.

The MY 1050S Automatic Die-Cutting Deep Embossing Machine is suitable for a wide range of industries:

Packaging: Production of cartons, boxes, and luxury packaging.

Printing Industry: High-precision labels, promotional materials, and decorative designs.

Stationery: Notebooks, folders, and specialty paper products.

Decorative Plastics & Laminates: Die-cut PVC, PET, and laminated sheets for industrial use.

Its combination of die-cutting and deep embossing makes it an essential solution for high-end production lines.

High Productivity: Fully automated processes reduce labor and increase throughput.

Consistent Quality: Precision alignment ensures uniform results.

Durable Design: Heavy-duty construction supports long-term operation.

Cost Efficiency: Reduced waste, labor, and energy consumption.

Certified Safety: Compliant with international safety and environmental standards.

The MY 1050S Automatic Die-Cutting Deep Embossing Machine delivers precision, reliability, and efficiency for modern industrial applications. Certified to international quality and safety standards, it provides consistent high-quality output while minimizing operational costs. Its robust design, user-friendly interface, and comprehensive technical support make it ideal for packaging, printing, and decorative industries worldwide.

Investing in the MY 1050S means faster production, superior design accuracy, and reduced downtime—making it a vital asset for industrial die-cutting and embossing operations.

RELATED

RELATED

RELATED

RELATED

This website uses cookies to ensure you get the best experience on our website.